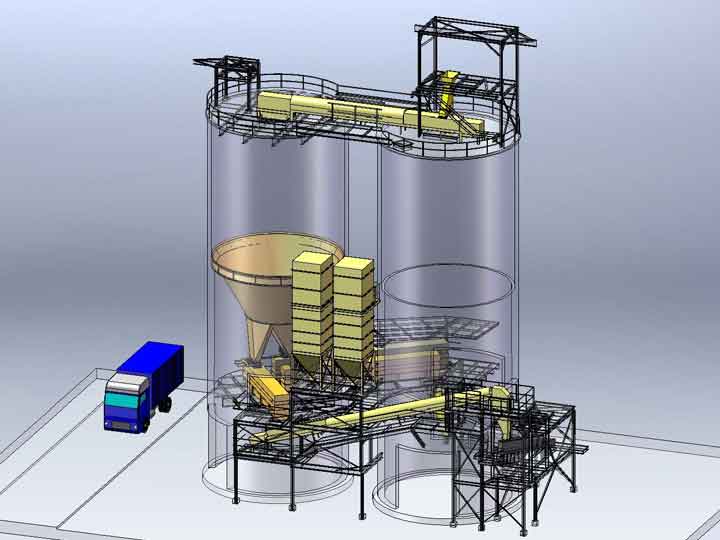

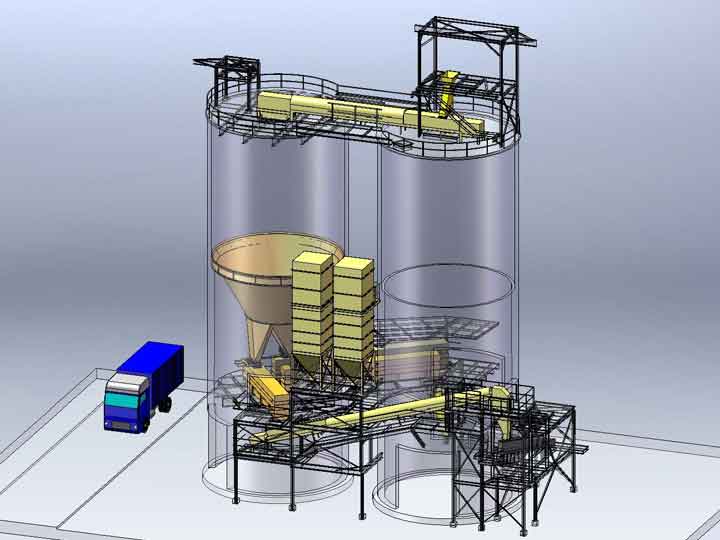

Coal Storage Silo

Specifications

The technology of silo storage for coal is often used in power plants and coal mines. Concrete silos and steel silos are both usually used as coal storage silos. A concrete silo requires a long construction period and high investment, but a steel silo can be quickly built with less budgets.

Coal storage silo are used in some power plants and coal mines. Concrete silo and steel silo are both wildly used in coal storage, concrete silos cost more money and time to built one. Since spiral coal storage silo is more popular and has more advantage than concrete silo. It is wildly used in the area of grain and oil, brewing, building materials, environmental protection, chemical industry, energy and other industries.

Advantages of our coal steel silo:

► Good overall performance, long service life: spiral seaming edge five times the parent metal thickness, which greatly strengthens the silos’body resistance to load capacity; its stability and strength service life are better than that of other steel silos.

► Good air-tightness, extensive usage: this seaming by special equipment bending forming , sealing performance is especially good; can be used in granular, powder, grain storage ; avoid external humidity influence in inside materials, and at the same time can satisfy the insecticidal, fumigation etc. process requirement, and can also be used to store liquid objects.

► Good air-tightness, extensive usage: this seaming by special equipment bending forming , sealing performance is especially good; can be used in granular, powder, grain storage ; avoid external humidity influence in inside materials, and at the same time can satisfy the insecticidal, fumigation etc. process requirement, and can also be used to store liquid objects.

► Short construction time, low installing cost: the silo body weight is equivalent to 1/6 of concrete silo with same volume , which greatly reduce the basic cost; at the same time extremely short construction period.

► Equipped with full set auxiliary according customer’s requirement: the silo equipped with conveyor, material level monitor, dust remover, etc. All auxiliary depended on the storage material.

Inquiry

INQUIRY